With today’s technology we have softwares for visualisation at disposal, but nothing can still compare to an actual physical product. Especially if this product is something new and we want to feel it with our hands, see how aesthetically and ergonomically it looks and feels in our hands, how practical it is for the intended purpose etc.

Until very recent the only way to have an actual physical product manufactured was to either machine it from the billet or maybe develop expensive castings for injection moulding only to realise the product has a fault you have not noticed on the screen. This way you are wasting time and money, many times leaving you with a product that does not completely satisfy your needs, but you have already spent too much money to go back to the drawing board.

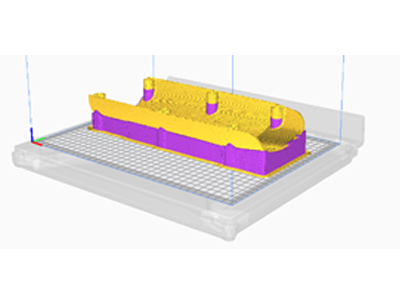

This issue can be almost fully resolved using rapid prototyping, additive manufacturing or, as majority of people know it, 3D printing.

Due to our customer needs for better, lighter and cheaper products we have invested into FDM (Fused Deposition Modelling) 3D printer. Every day it is being used for developement of prototypes, testing before further investing, and in some cases even for final products. This technology allows us to offer the following services within this sector: